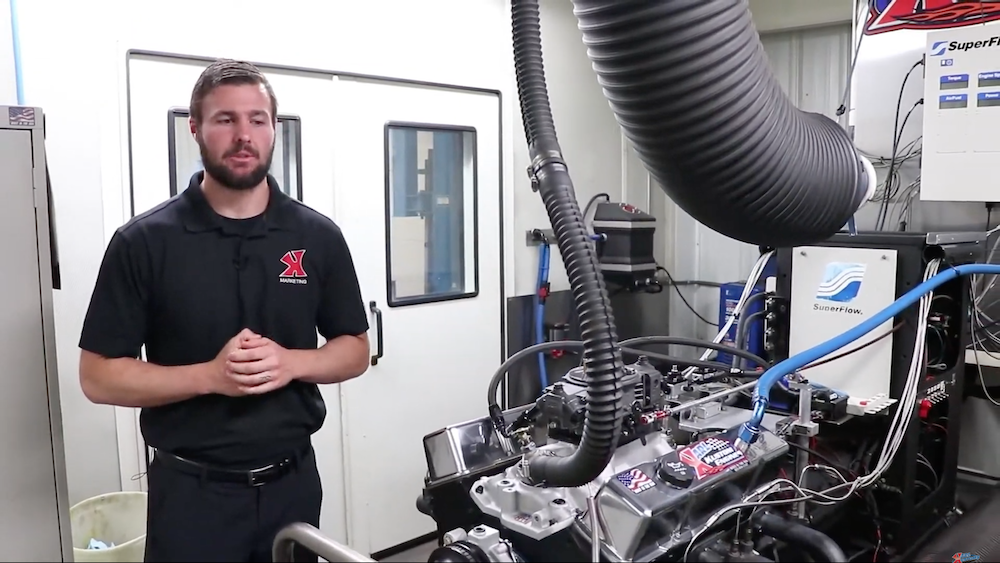

Inside The Engine Dyno Room

The engine dyno is used in a variety of ways. From breaking in a new crate motor to diagnostics, dynos are an invaluable tool.

Ever wondered what exactly an engine dyno does? They’re used for far more than just tracking horsepower and torque curves.

Our machine shop manager Kelly Tapper recently granted an inside look at just how useful the dyno room can be. If you love graphs, charts, and cars this is right up your alley.

Engine Dyno Uses

Our team at Karl Kustoms uses a SuperFlow Dyno. It’s useful for breaking in engines, performance tuning, diagnostic/system checks, and much more. In regards to breaking in a new engine, Tapper had plenty of information to share.

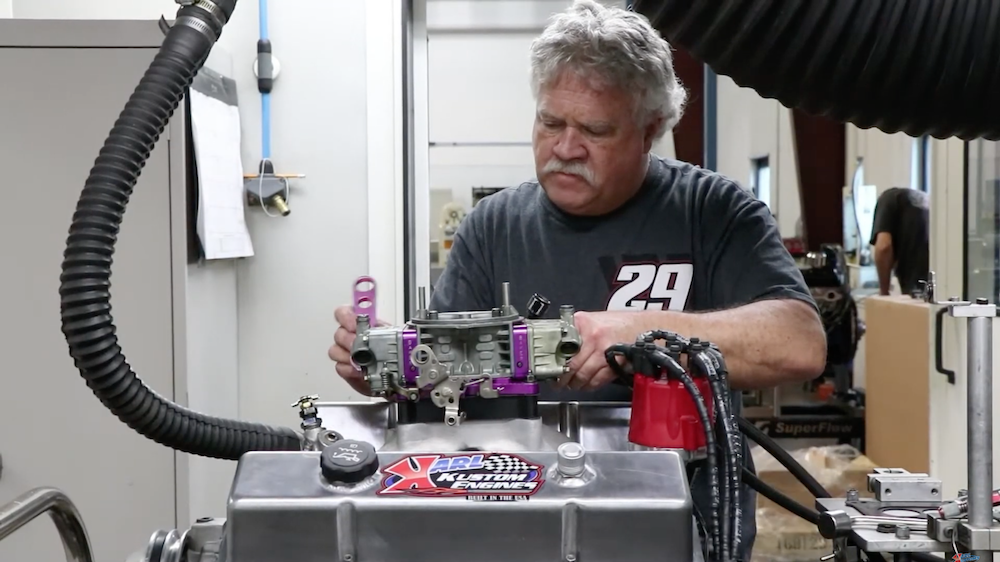

“We will take a carburetor that we know is already setup good, that we don’t have to worry about. We’ll do the base timing check on it. We’ve got the EGT setup so we can measure the temperatures per cylinder… And we can watch the fuel chart as it goes up.”

“We’ll put a slight load on that thing for about 30 minutes or so,” says Tapper “Add about 1300º F per cylinder to get some good temperature in the combustion chamber and the rings to get everything to seat in properly. We’ll have it sitting there maybe around 3000-3500 rpm varying the timing and changing the load on it as the 30 minutes pass by until the rings seat in.”

Engine Dyno Tuning And Diagnostics

When it comes to tuning, the dyno is the most valuable tool available. If a customer wishes to tune a part we can use the dyno to track exactly what is happening and what needs to change to get that extra power bump.

But not everything is smooth cruising and power building. Often times, customers need to find the source of a performance issue. Once again, the dyno is perfect for just such a thing.

“You would be surprised the amount of stuff that is inside these carburetors, especially on the dirt track… anything from debris in the fuel bowl or air bleeds that the customer’s telling me is not working. We’ll go and figure out what it is or clean it out while it’s here.”

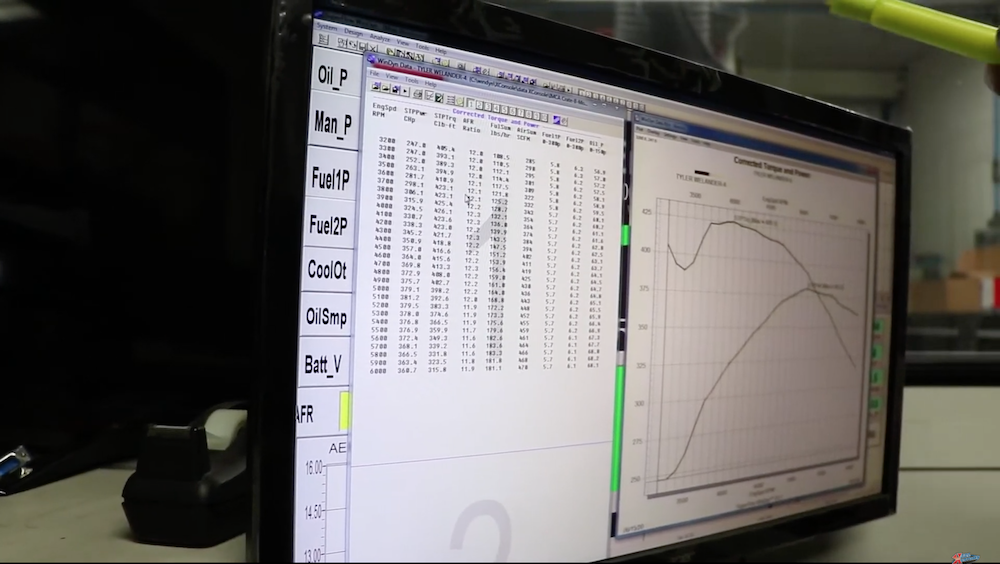

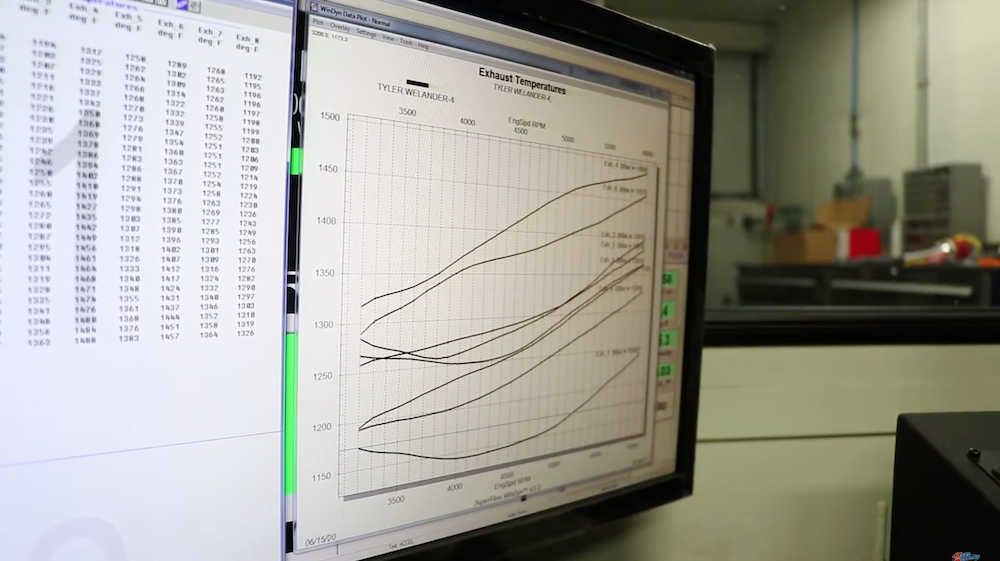

Tapper shows exactly how the computers are used to chart the various metrics recorded by the dyno. The greatest benefit of the dyno is the live data feed. This data includes information like:

- Horsepower

- Torque

- Oil Pressure

- Coolant Temp

- EGT (exhaust gas temperature)

- AFR (Air-Fuel Ratio)

- And more

Tapper shares that this data is “Very useful to the trained eye.” It allows the team to catch many issues before they can become a real problem. And if our team can’t figure out a particular issue, our vast network of colleagues are always available to jump in and provide assistance.

Regardless of the situation, we always get our results.

Parting Words

When asked about the one piece of advice for engine building Tapper was quick to answer:

“Quality. Don’t skimp on some of the parts. I know that a lot of guys are looking to save a buck, but the hassles that you’re gonna find down the road are gonna outweigh your happiness… it usually ends up biting you.”

If you’re in need of engine building help or are looking to dyno your motor, contact our crew at Karl Kustoms. We’ve got decades of experience, the right network, and the proper knowledge to help with your project!

And for more videos like this, be sure to visit our YouTube Channel!